Microwave sintering time optimization to boost structural and electrical properties in BaTiO3 ceramics

Abstract

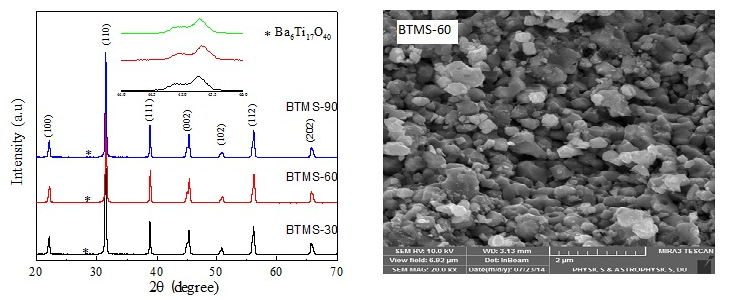

BaTiO3 ceramics with fine grain distribution were successfully fabricated by solid state reaction using microwave processing. The role of microwave sintering time for producing a controlled microstructure with optimized dielectric and ferroelectric properties in BaTiO3 ceramics is discussed. X-ray diffraction data were refined with Fullprof program using Rietveld method, which showed perovskite-type tetragonal structure with space group P4mm for all prepared samples. The scanning electron microscope (SEM) revealed that the grain size found to increase with increasing microwave sintering time. Dielectric constant (εr) measured in frequency range 0.1 Hz to 5 MHz at different temperatures showed depressive behaviour in the higher frequency region which decreases with increasing frequency. The BaTiO3 sample sintered at 1200 °C for 60 minutes exhibited best properties as high dielectric constant (εr≈1.5x104) with lowest degree of diffuseness (γ≈1.0741). The ferroelectric properties were investigated using P-E hysteresis loop. The remnant polarization (Pr) increased while the coercive field (Ec) decreased with increasing microwave sintering time applying these are micro structural dependent. Optimum sintering time has been found resulting in high values of relative permittivity and remnant polarization.Â

ISSN 2321-4635

ISSN 2321-4635