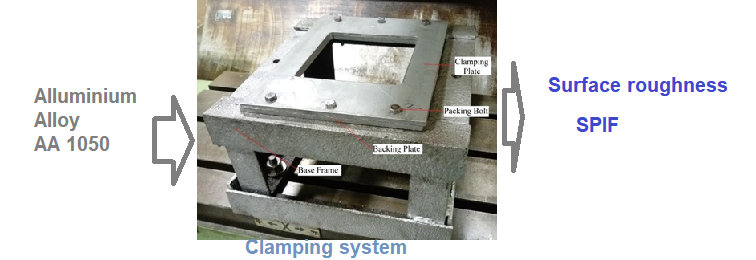

Single Point Incremental Forming (SPIF) of Aluminum Alloy AA 1050: Experimental evaluation of the effect of process parameters on surface roughness

Abstract

The work on single point incremental forming of Aluminium alloy (AA1050) was done experimentally. The impact of process variables including tool shape, tool size, step size, and feed was examined on surface roughness. Research was conducted utilizing the Response Surface Methodology (RSM). The relevance of process parameters was determined using analysis of variance (ANOVA). The tool's form was found to have the biggest impact on surface roughness. The surface roughness is also greatly influenced by the tool size and step size. Higher feed rates can be used without degrading surface quality since feed has the least impact on surface roughness.

Keywords

Single point Incremental Forming; AA 1050; Surface Roughness; metal surface; metal compression;

ISSN 2321-4635

ISSN 2321-4635