Computational fluid flow analysis of elasto hydro-dynamic lubrication journal bearing

Abstract

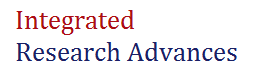

In Elasto hydro dynamic lubrication occurs when a lubricant is introduce between the load carrying surfaces that are in rolling contact such as mating gears or bears. A lubricant presents metal to metal contact and the stability of surfaces can be determined by fluid dynamic laws. It is necessary to determination of bearing used under high loading condition in situation like engines which otherwise neglected therefore hydrodynamic lubrication analysis of journal bearing plays an important role in study of journal bearing, the relation between determination and oils film pressure on a journal bearing surface can be determined using structural analysis. A computational flow analysis gives a film pressure in this project the journal bearing are analyzed for Elasto hydro dynamic model using fluid structure interaction and computational fluid dynamic approaches, the analysis is carried out using SAE20W oil for different eccentricity values length to diameter ratio of 2.0, 2.1, 2.2, 2.3 and 2.4. The pressure field obtained from fluid dynamics is used in structural analysis to determine the displacement and stresses occurring in mating surfaces. Laminar steady flow is considering in fluid dynamics and aluminum, is considered as material in structural analysis. The CFD results are tested against analytical results before parametric study carried out. As length to diameter ratio increases from 2.0 to 2.4 the pressure values for lubricating using SAE20W oil increases from 3.3 bars to 3.6 bars respectively. It is observed that for increases in L/D ratio from 2.0 to 2.4 displacement values increases from 0.0098m to 0.014m and stresses increases 29.24 to 36.65 N/m2.

Keywords

journal bearing; SAE20W oil; Aluminum; L/D Ratio; eccentricity

Full Text:

PDFRefbacks

Â Â Â Â Â Â Â Â Â Â |

ISSN: 2456-334X

ISSN: 2456-334X